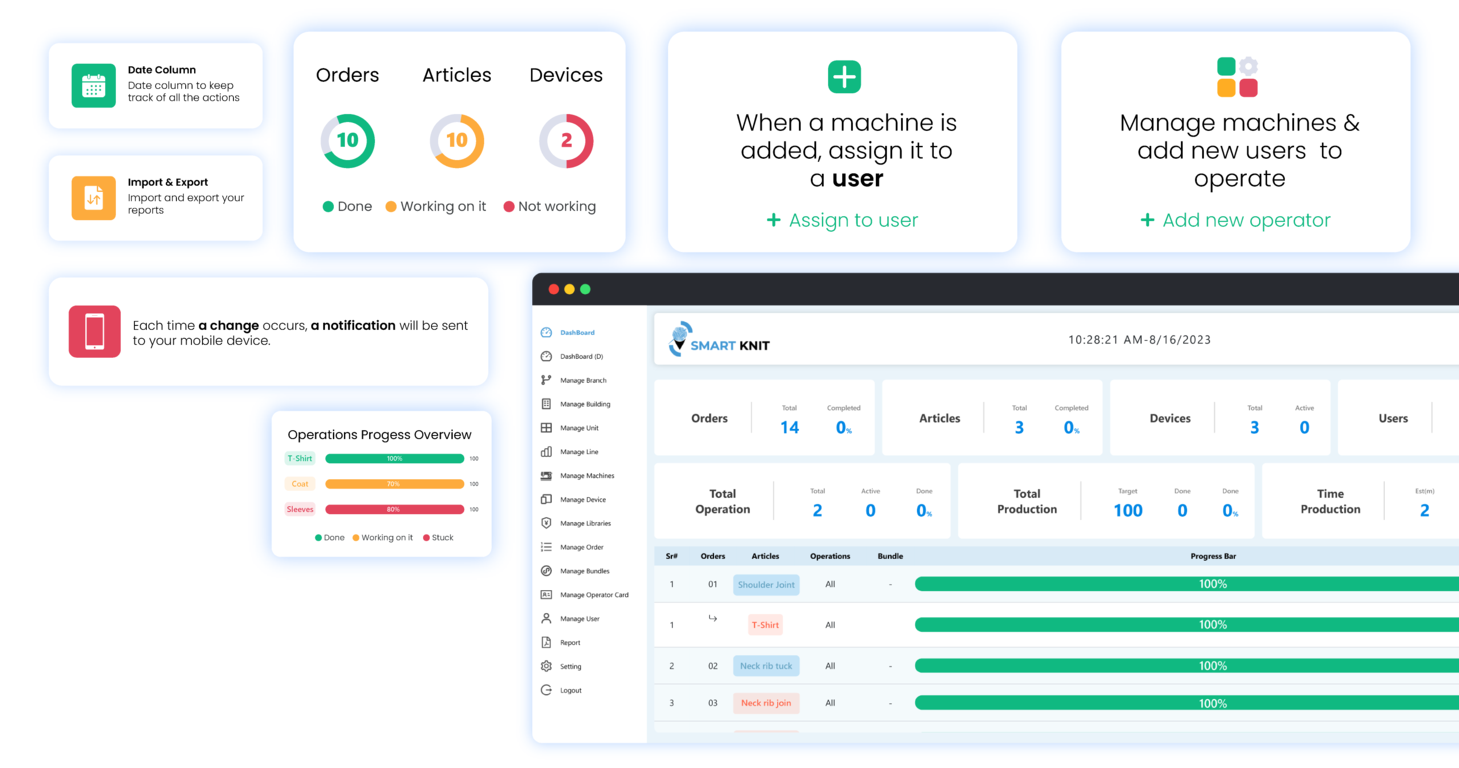

Navigate the Future with SmartKnit's Advanced Control and Analytics Hub

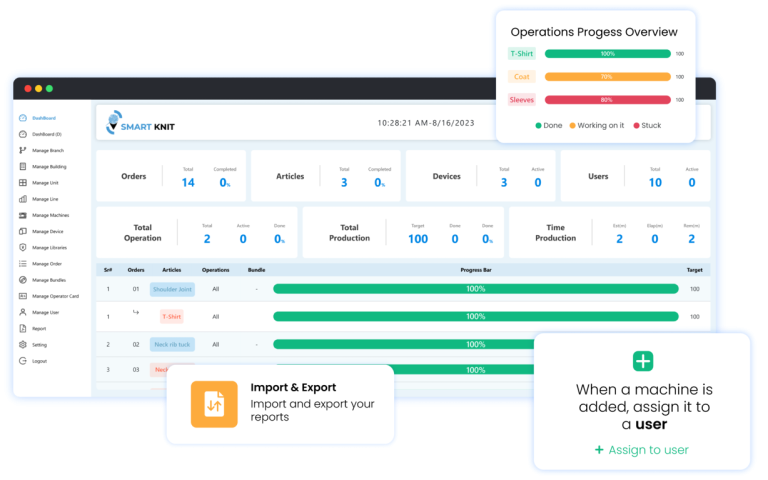

The SmartKnit dashboard offers a comprehensive view of ongoing production in the manufacturing facility. It provides a clear count of active orders, aiding managers and operators in swift workload assessment and task prioritization.

Dashboard

Real-time Insights for Enhanced Efficiency and Informed Operations

It highlights the status of IoT devices engaged in the production, encompassing sensors and controllers. Real-time data on active operators ensures proper staffing and efficient resource allocation.

Furthermore, the dashboard showcases the number of engaged operators. The total production output is visually presented, offering insights into factory efficiency and overall productivity across a defined timeframe. This valuable information aids in evaluating factory performance and establishing production objectives.

Efficient Reporting

Enhanced Reporting for Optimal Production Insights

The reporting feature automates the generation of detailed reports summarizing production line activities. These reports include historical data about production rates, machine downtimes, operator performance, and other relevant metrics. Such reports are invaluable for performance analysis, identifying bottlenecks, and making data-driven improvements to the manufacturing process.

Comprehensive Analytics

Explore Every Detail with SmartKnit's Analytics Suite

This feature allows users to delve into detailed analytics and management of various aspects related to the manufacturing process. It covers articles (products being manufactured), styles (design variations of the articles), sizes, colors, brands, machines, and operators. Users can access information on production trends, preferences, equipment performance, and operator efficiency, facilitating informed decision-making.

Production Tracking & Alerts

Real-Time Production Insights and Alerts for Seamless Operations

This functionality provides a real-time overview of the ongoing production process and machine activities. It includes automated alerts that notify users about any unexpected events, delays, or issues on the factory floor. This real-time tracking helps in swiftly addressing disruptions and maintaining a consistent production flow.

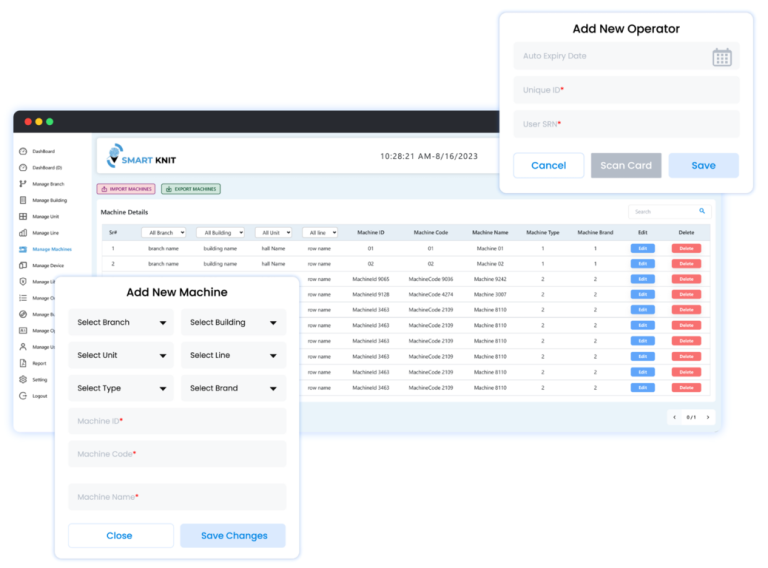

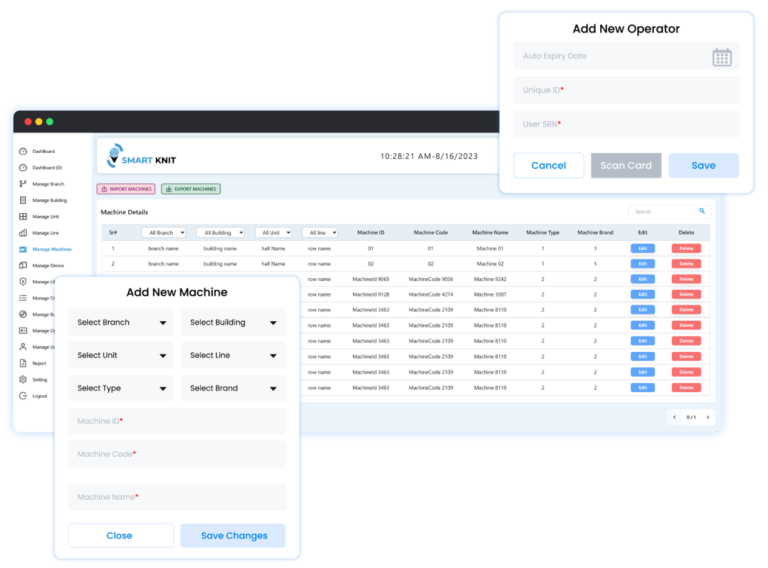

Seamlessly Organize and Optimize Your Operations with Smart Management Tools

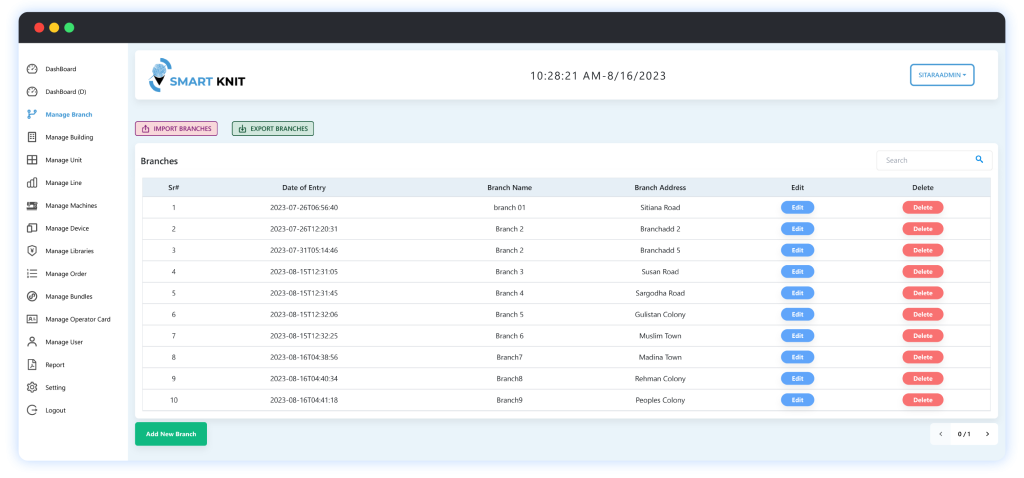

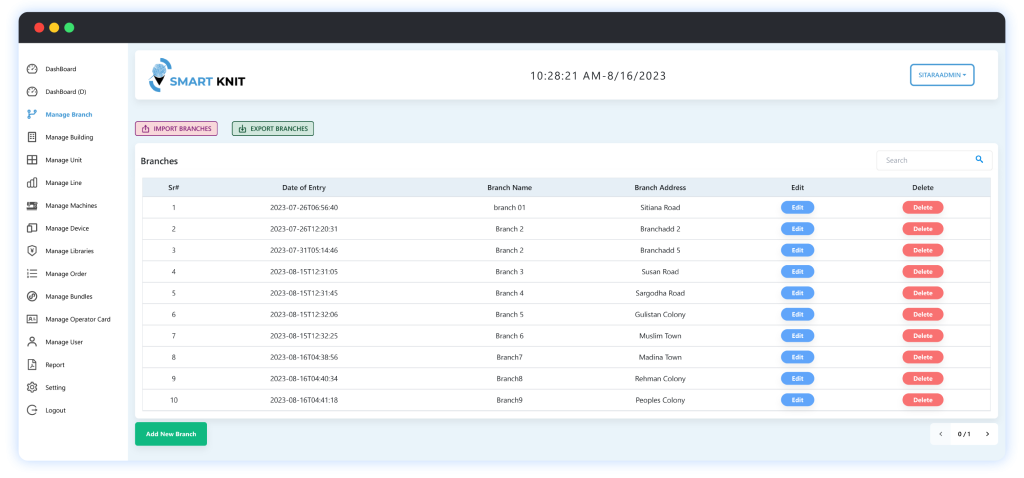

- Branch Management

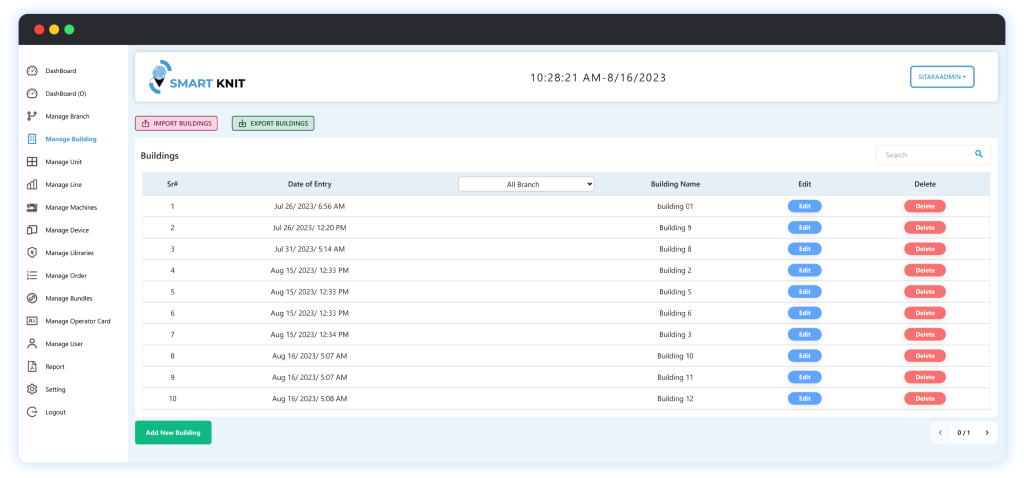

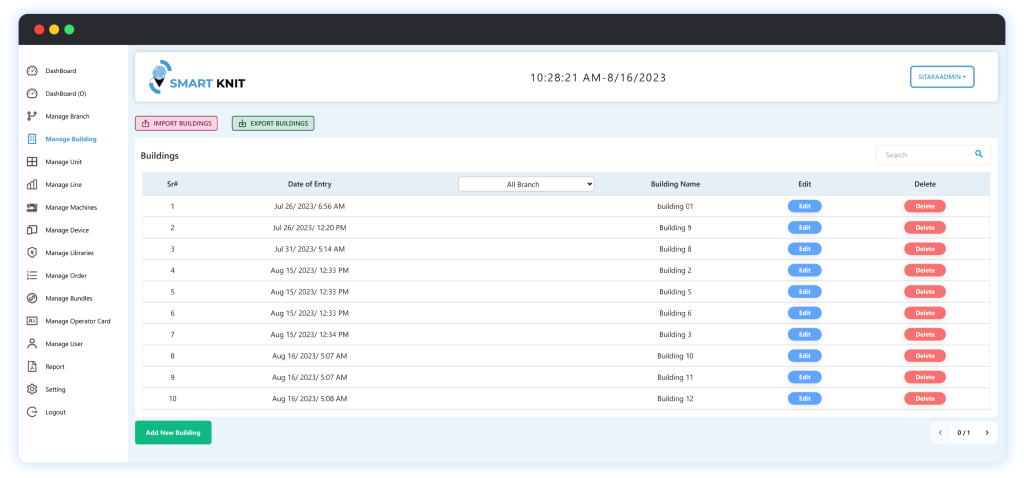

- Building Management

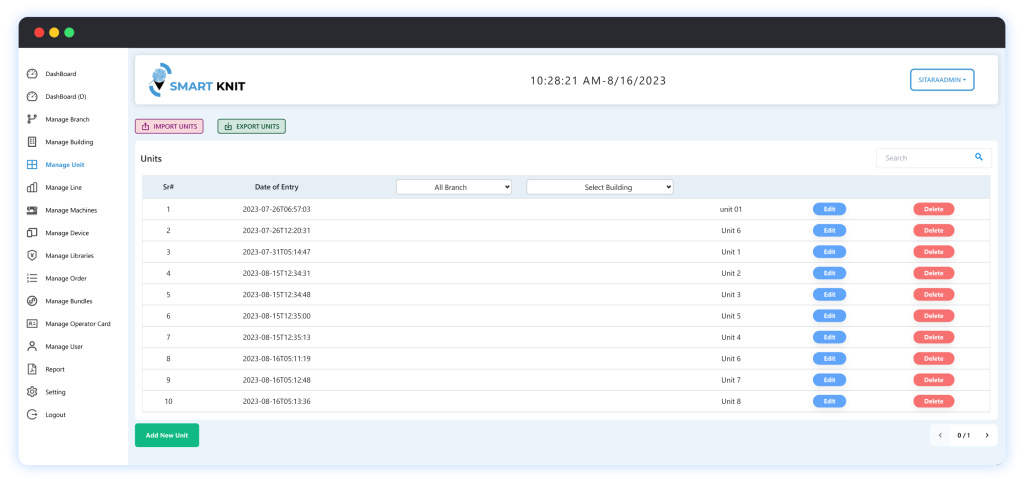

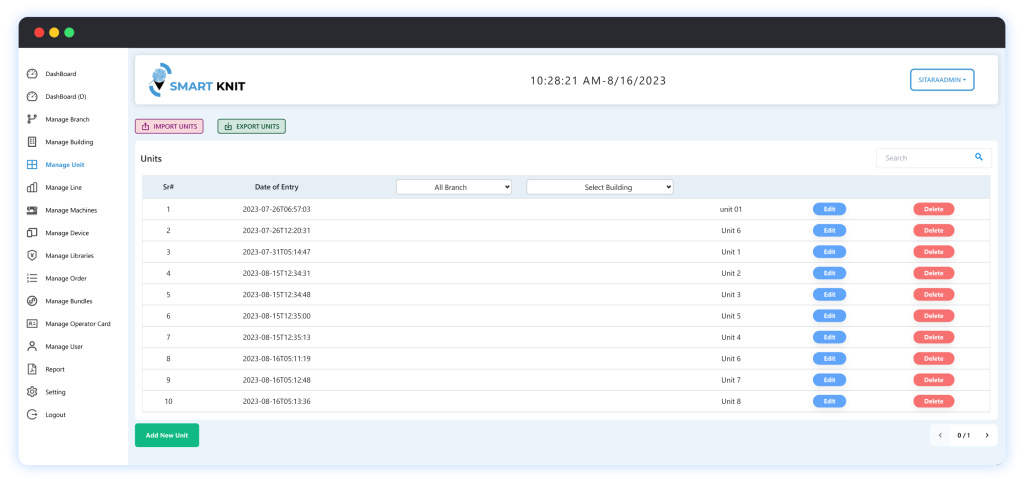

- Unit Management

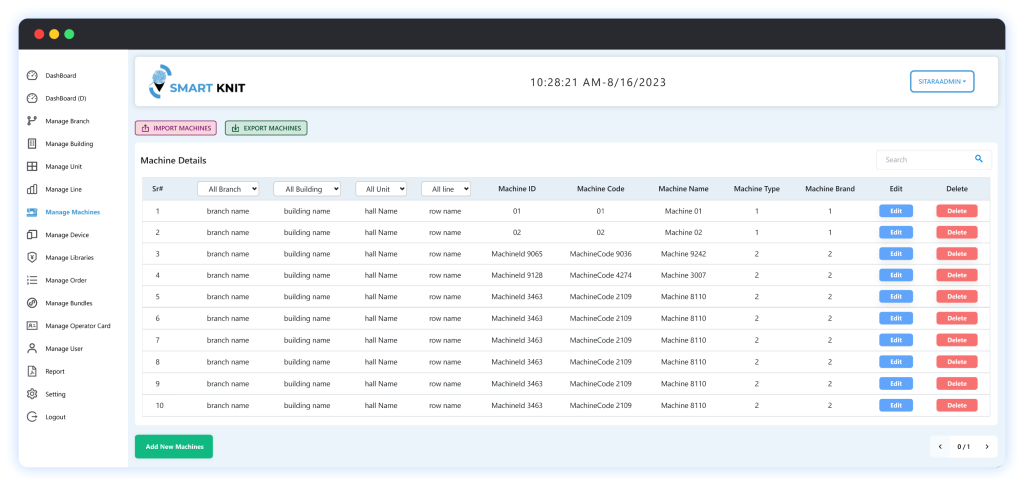

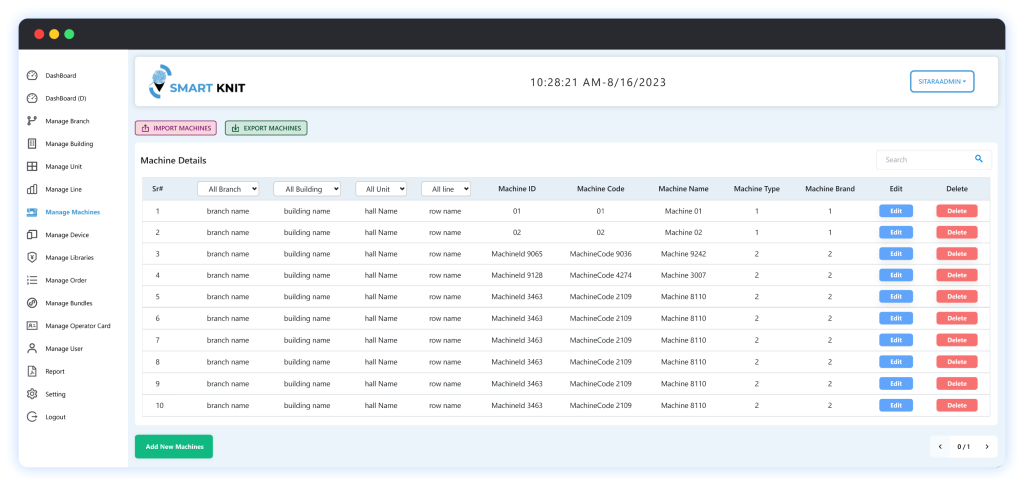

- Machines Management

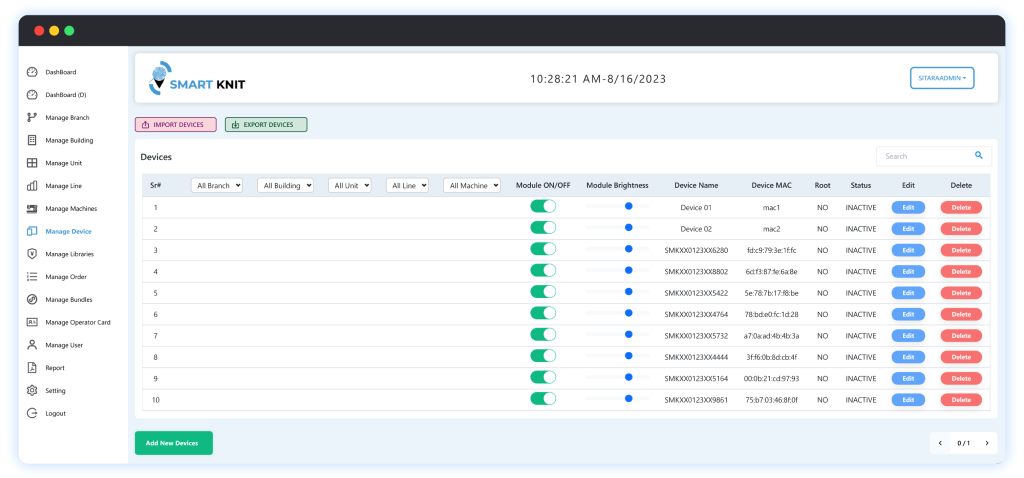

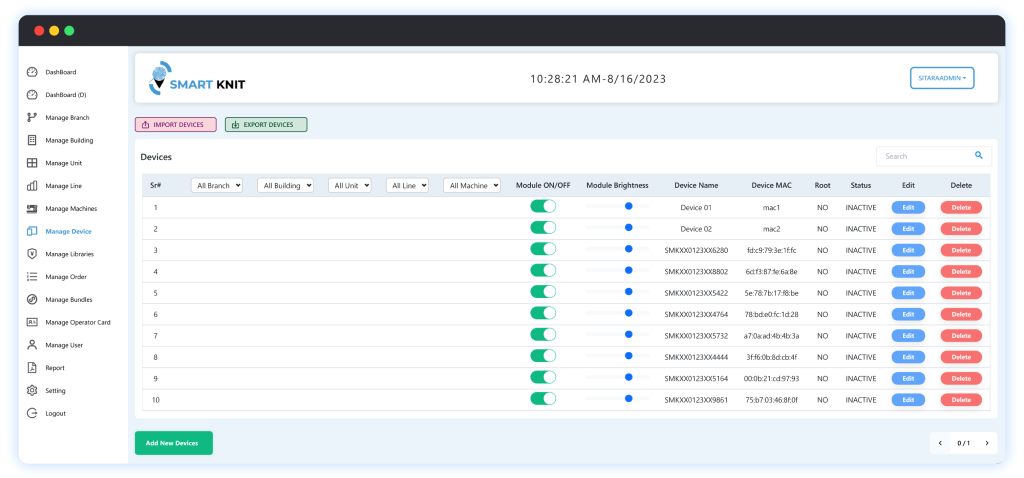

- Devices Management

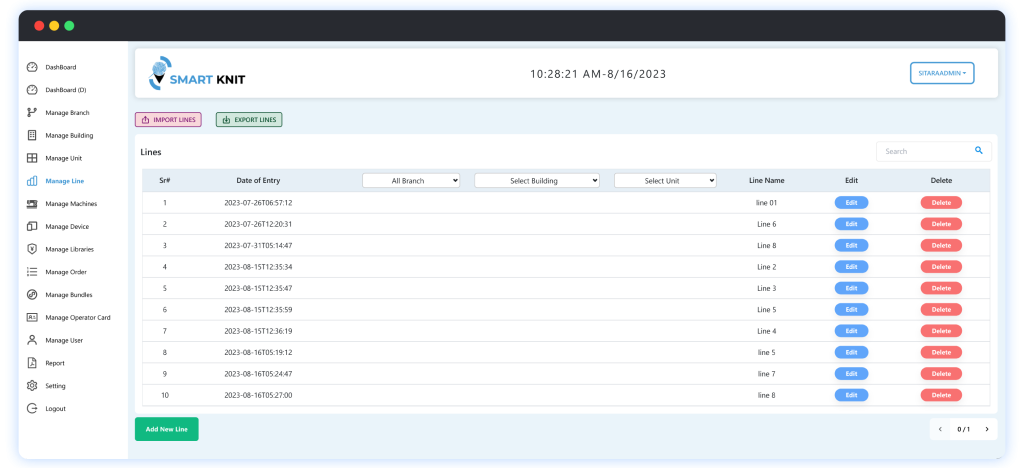

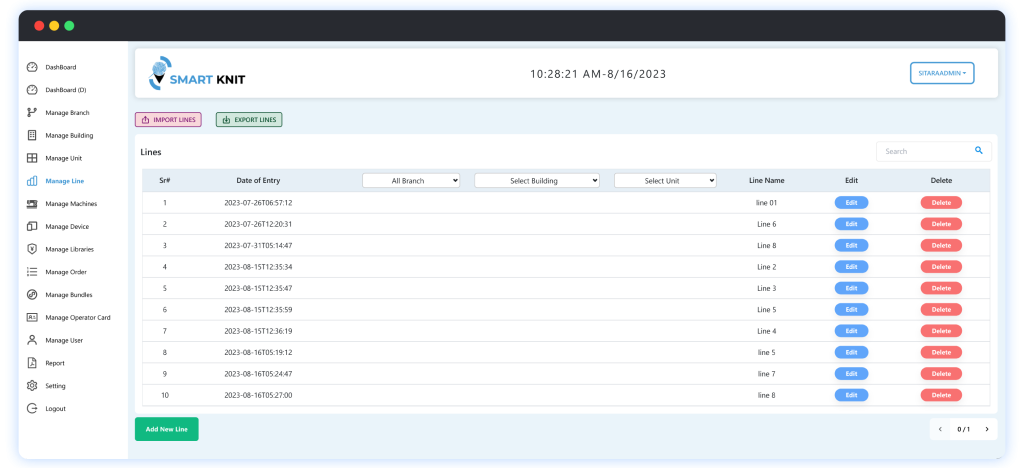

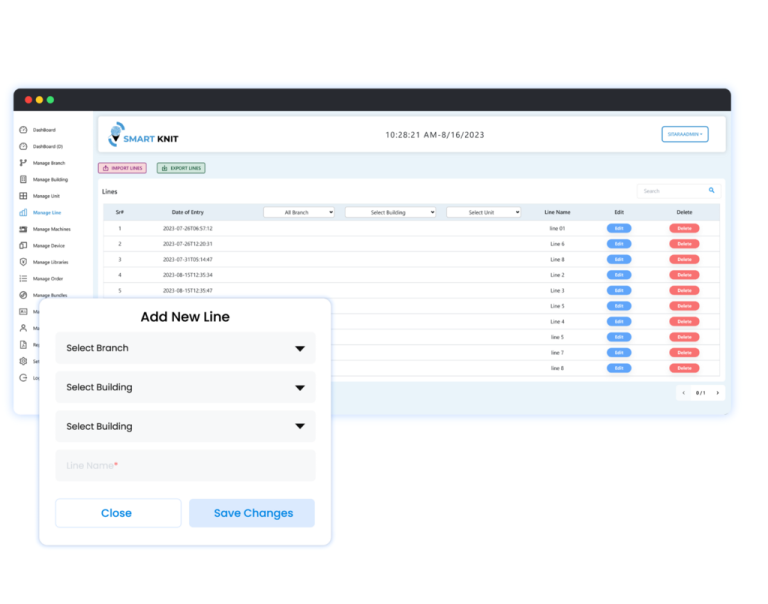

- Line Management

Effortlessly add, edit, and delete branches with SmartKnit. Keep your organizational structure up-to-date and well-organized for streamlined management and communication.

Add, edit, and delete buildings effortlessly with SmartKnit for streamlined organization and efficient management.

Add new units seamlessly, edit existing ones, and remove units no longer needed. Streamline your organizational structure and keep unit information up-to-date effortlessly.

Keep your equipment records organized and up-to-date for streamlined operations. Add new machines, import/export data, edit existing entries, and remove machines when necessary.

Manage devices effortlessly using SmartKnit. Add new devices, edit existing ones, and remove devices as needed. Keep your device information up-to-date and organized for seamless operations.

Simplify line/row management with SmartKnit. Add new lines, edit existing ones, and delete lines as required. Keep your production lines organized and up-to-date for smoother operations.

Seamlessly Organize and Optimize Your Operations with Smart Management Tools

- Branch Management

- Building Management

- Unit Management

- Machines Management

- Devices Management

- Line Management

Effortlessly add, edit, and delete branches with SmartKnit. Keep your organizational structure up-to-date and well-organized for streamlined management and communication.

Add, edit, and delete buildings effortlessly with SmartKnit for streamlined organization and efficient management.

Add new units seamlessly, edit existing ones, and remove units no longer needed. Streamline your organizational structure and keep unit information up-to-date effortlessly.

Keep your equipment records organized and up-to-date for streamlined operations. Add new machines, import/export data, edit existing entries, and remove machines when necessary.

Manage devices effortlessly using SmartKnit. Add new devices, edit existing ones, and remove devices as needed. Keep your device information up-to-date and organized for seamless operations.

Simplify line/row management with SmartKnit. Add new lines, edit existing ones, and delete lines as required. Keep your production lines organized and up-to-date for smoother operations.

Performance Evaluation

Gauge, Balance, and Boost Your Production Performance

This screen enables the evaluation of key performance indicators such as estimated throughput, production line balance, and efficiency. Throughput refers to the rate of production, while production line balance assesses workload distribution among different stages of the process. Efficiency measures how effectively resources are utilized to achieve production goals. This feature helps managers optimize processes for higher productivity and reduced waste.

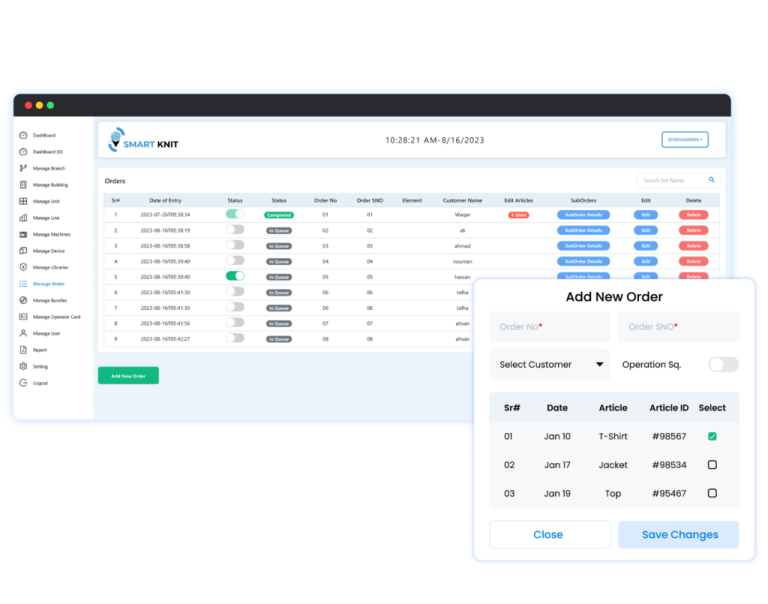

Order Management

Customize and Modify Production with Ease

Create Order with Multiple Variations: Users can create new production orders with multiple variations. Variations could include different styles, sizes, colors, and other customizable features. It simplifies the process of initiating new manufacturing runs by accommodating the diverse requirements of customers and products.

Edit Existing Order: Users can modify and update details of existing production orders. Changes may include adjusting quantities, altering specifications, or making any necessary amendments to accommodate changing requirements or unforeseen circumstances

Contact us to learn how smartknit can help you

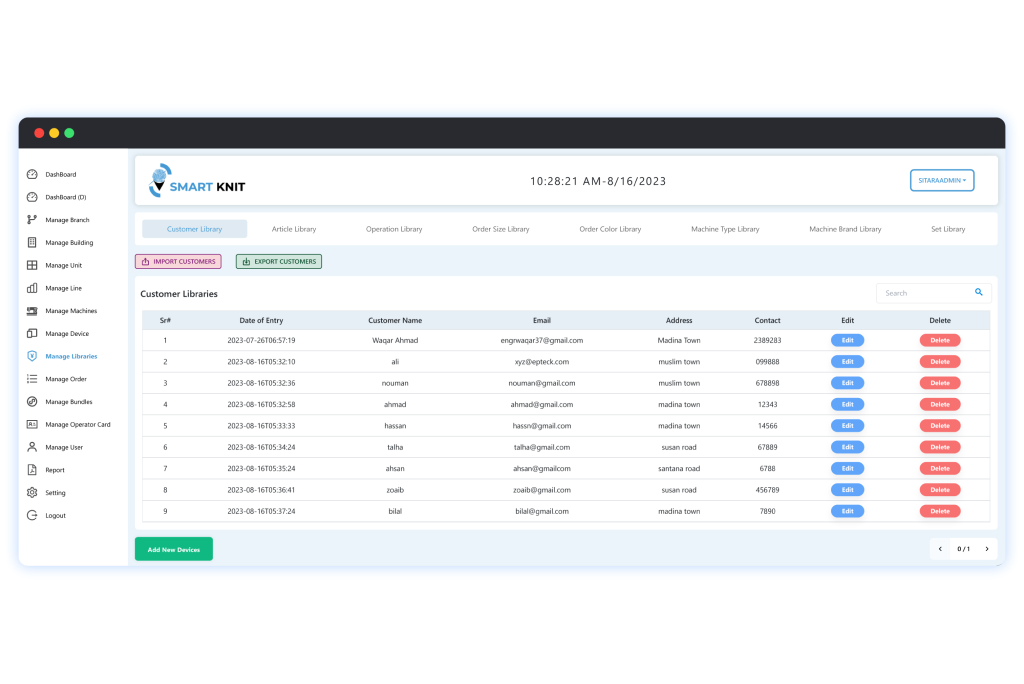

Library Management Organize Your Resources for Smooth Operations

Customer Library

This streamlined functionality ensures that customer data is up-to-date and easily accessible, contributing to smoother communication and enhanced customer relationship management. Users can effortlessly add new customers to the system, inputting essential details to maintain accurate records. Additionally, the library enables the editing of existing customer profiles, facilitating updates to contact information or other pertinent data.

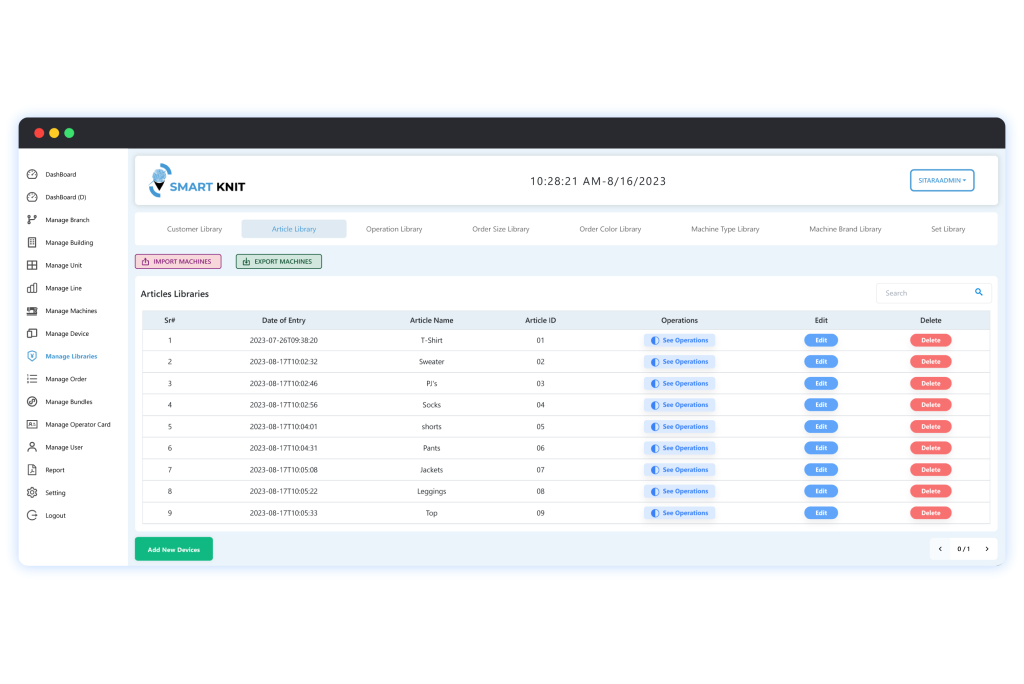

Article Library

This feature ensures that the product lineup remains accurate and up-to-date, contributing to streamlined production and informed decision-making. Users can effortlessly add new articles, providing essential details about each product. The library also enables the editing of existing article profiles, facilitating updates to specifications or other relevant information.

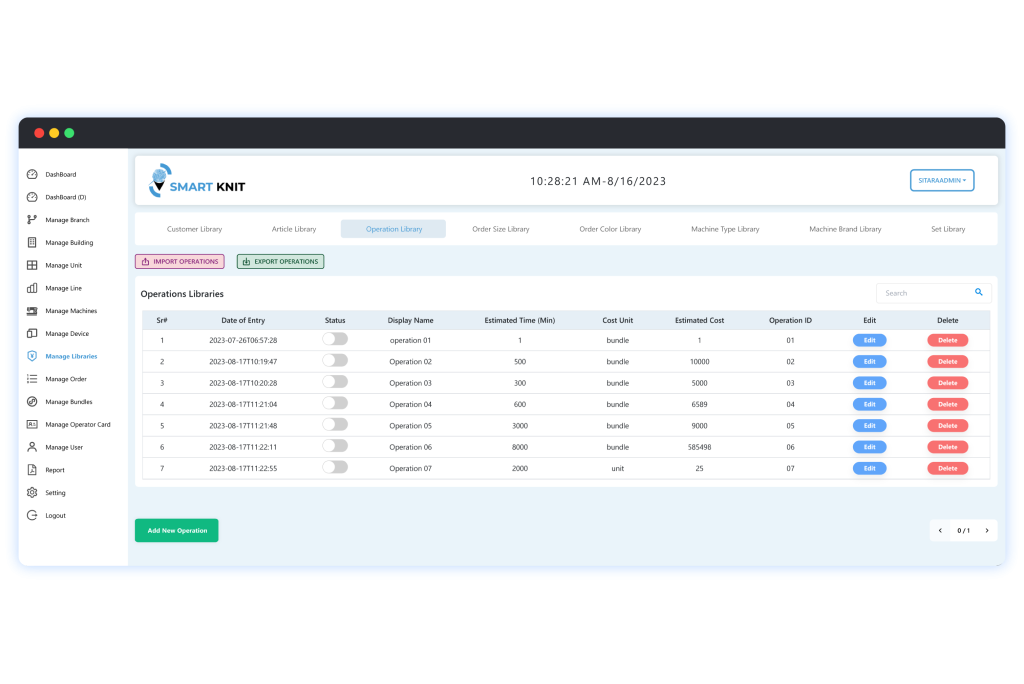

Operation Library

This feature ensures that the production process is accurately documented and adaptable to changing requirements. Users can efficiently add new operations to the system, providing detailed descriptions and specifications. The library also facilitates the editing of existing operation profiles, allowing for updates and modifications as needed.

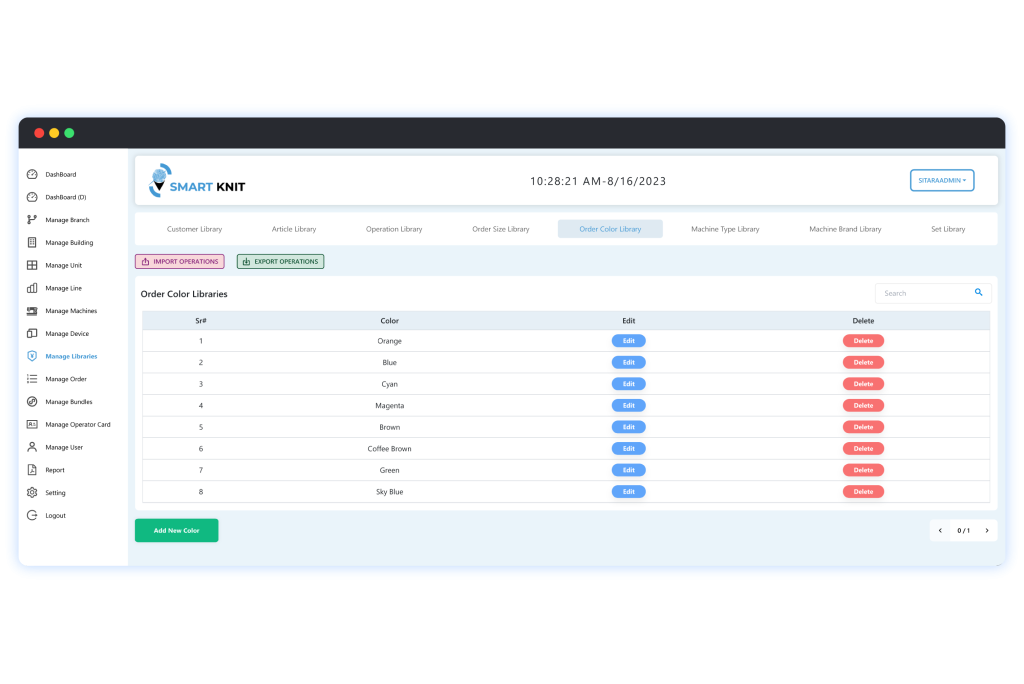

Order Library

By centralizing size and color information, SmartKnit enhances order customization and overall operational effectiveness. This feature ensures that the size and color options for orders are well-organized and up-to-date, contributing to smoother order processing and production planning. Users can easily add new size/color options to the system, specifying the dimensions or hues required. This ensures accurate representation of the product variations.

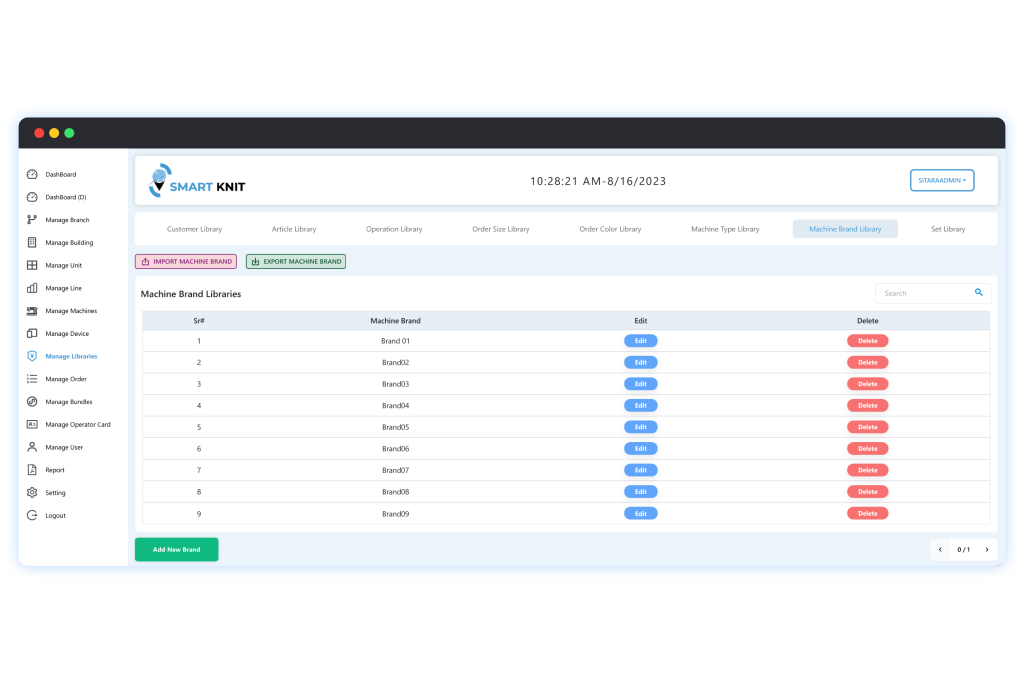

Brand Library

This feature ensures that the manufacturing process is equipped with accurate and up-to-date machine information, contributing to streamlined operations and informed decision-making. By centralizing machine type and brand data, SmartKnit enhances equipment management and overall operational efficiency. The library also allows for the editing of existing machine type/brand profiles, making updates or modifications hassle-free.